Vincentzeng

Leave a messageMaterial:PET/PC/PP

Thickness:0.05mm-2.0 mm Structure

Overlay with printing+Rear Adhesive

Description:

Touch Flat Overlay

Keys embossed Overlay

Application:

Remote controller,Fridge,Washing machine,Medical instrument

Self-adhesive Label manufacturers are companies that specialize in the production and supply of Self-adhesive labels. These labels are widely used in various industries, including retail, pharmaceutical, food and beverage, logistics, and many others. In this article, we will discuss the role of Self-adhesive label manufacturers, the materials they use, the production process, and important considerations when choosing a reliable manufacturer.

Self-adhesive labels are labels that have an adhesive backing, allowing them to be easily attached to various surfaces such as packaging, products, or documents. These labels are commonly used for branding, product information, tracking codes, barcodes, and other purposes. The popularity of self-adhesive labels can be attributed to their versatility, ease of use, and wide range of design options.

Self-adhesive label manufacturers play a crucial role in the production and supply chain of labels. They are responsible for meeting the specific requirements of their clients by producing labels in different shapes, sizes, and designs. Manufacturers work closely with their clients to understand their needs and provide customized solutions. This involves selecting the appropriate label material, adhesive, printing techniques, and finishing options.

Label materials for self-adhesive labels can vary depending on the specific application and the desired characteristics of the labels. Common materials include paper, synthetic materials like polyester or polypropylene, and specialized materials like tamper-evident or security labels. The choice of material affects the durability, aesthetics, and performance of the labels. Manufacturers have the expertise to recommend the most suitable material based on the client's requirements.

The production process of self-adhesive labels involves several steps. It starts with pre-press activities like artwork design and color separation. This is followed by the printing process, which can be done using different techniques like flexographic, offset, or digital printing. After printing, the labels undergo finishing processes such as die cutting, laminating, and varnishing. Finally, the labels are wound onto rolls or sheets and prepared for shipment.

When selecting a self-adhesive label manufacturer, there are several important considerations to keep in mind. Firstly, the manufacturer should have a good reputation and a track record of delivering high-quality products. This can be assessed by checking customer reviews, certifications, and industry recognition. Secondly, the manufacturer should have sufficient production capacity to meet the client's requirements in terms of volume and turnaround time. This includes having modern machinery and equipment, skilled labor force, and quality control systems. Additionally, the manufacturer should offer competitive pricing and flexible options for customization to cater to the client's specific needs.

In conclusion, self-adhesive label manufacturers serve a crucial role in the production and supply of labels. They provide customized solutions for various industries by selecting the appropriate materials, printing techniques, and finishing options. When choosing a manufacturer, it is important to consider factors such as reputation, production capacity, and pricing. By partnering with a reliable self-adhesive label manufacturer, businesses can ensure the quality and effectiveness of their labeling solutions.

13+ years experience work for membrane switch, overlay and nameplate products for our team.

One-stop process for membrane switch&product identification

Fully technology support from design to Mass Production.

Keep Improving by Quality First &Best Service to exceed customer’s expectations

Rapid Prototype Membrane Switches and Overlays by Fully automatic digital printing equipment + Automatic digital cutting prototype machine

5-7 days from design for approval.

Fully automatic digital printed graphics

Fully automatic digital die cut size

Automatic Screen printed graphics

Automatic Rotary printed graphics

Transparent tinted window options

Additional components such as rubber keypad assemblies

Backlighting options such as Light Guide Plate (LGP),Light Emitting Diodes (LED)

The company integrates design, research and development,manufacture and sales as one of the comprehensive enterprise.

Kunshan Begao Electronic Technology Co., Ltd. specializes in the design and production of membrane switch, overlay, flexible switch, label&Nameplate and capacitive touch circuit products. We Have a 100,000-level standard dust-free workshop, imported professional production equipment and a technical team with an experience of more than 10 years in the industry.

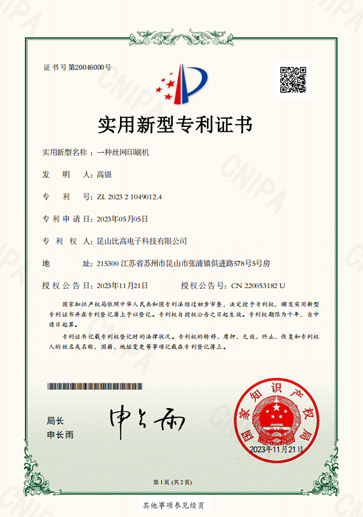

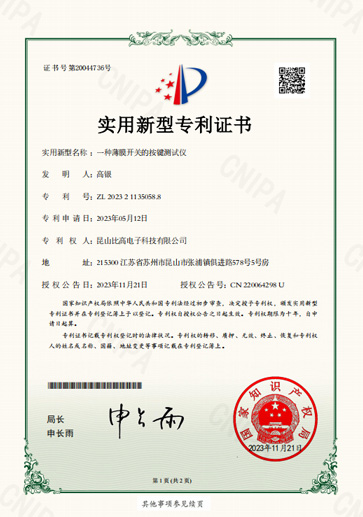

And we have acquired ISO9001:2008 international quality system and more than 18 professional technology patents and all the materials used meet the RoHS test standards.

Establish a stable and cooperative relationship with well-known domestic and foreign electronics enterprises such as: Sensata, Flextronics, Joyoung,Leadman, Zola, Zoomlion

RELATED

RELATED

RELATED

RELATED