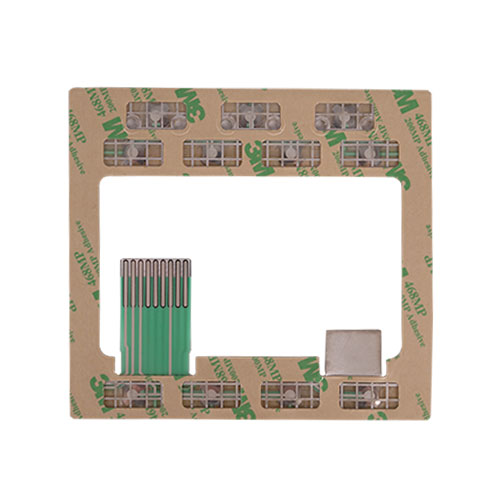

flexible circuit technology, also known as flex circuitry, is a specialized form of electronic packaging that is highly coveted due to its versatility and unique attributes. It involves the use of flexible substrate materials, such as polyimide, which offer several advantages and find numerous applications in various industries.

One of the primary advantages of flexible circuit technology is its ability to conform to irregular shapes and contours. Unlike traditional rigid circuit boards, flexible circuits can be bent, twisted, and folded without damaging the circuitry. This flexibility allows for greater freedom in the design and form factor of electronic devices. It enables efficient use of available space and facilitates the integration of electronics into small and complex systems.

Another advantage of flexible circuit technology is its excellent weight and size reduction capabilities. Compared to their rigid counterparts, flexible circuits are significantly lighter and occupy less physical volume. This attribute is particularly beneficial in applications that require miniaturization and lightweight design, such as mobile devices, wearable technology, aerospace equipment, and medical implants.  Flexible circuits also exhibit enhanced reliability and durability. The absence of solder joints and connectors, which are common failure points in traditional circuits, reduces the risk of mechanical and electrical failures. Moreover, flexible circuits are resistant to vibrations, shocks, and thermal stresses, making them suitable for demanding environments and applications that involve repeated movements or extreme conditions.

Flexible circuits also exhibit enhanced reliability and durability. The absence of solder joints and connectors, which are common failure points in traditional circuits, reduces the risk of mechanical and electrical failures. Moreover, flexible circuits are resistant to vibrations, shocks, and thermal stresses, making them suitable for demanding environments and applications that involve repeated movements or extreme conditions.

In terms of electrical performance, flexible circuit technology offers several advantages. Its thin and lightweight construction allows for improved electrical signal integrity and reduced transmission losses. Furthermore, the use of polyimide substrates with low dielectric constant and loss tangent results in excellent high-frequency characteristics. This makes flexible circuits suitable for applications requiring high-speed and high-frequency signals, such as telecommunications, data communication, and RF devices.

The unique attributes of flexible circuit technology have led to its widespread adoption in various industries and applications. In the consumer electronics sector, flexible circuits are used in smartphones, tablets, and wearable devices to enable miniaturization, improve mechanical robustness, and enhance user experience. They are also utilized in automotive electronics for electronic control units, dashboard displays, lighting systems, and sensors.

The aerospace and defense industry extensively employs flexible circuit technology due to its ability to withstand harsh environments, reduce weight, and enhance reliability. These circuits can be found in aircraft avionics, satellites, military communication systems, and radar systems.

In the medical field, flexible circuits are increasingly being used in medical devices and implants due to their biocompatibility, lightweight nature, and ability to conform to the body’s contours. They enable advancements in diagnostic imaging, electrocardiogram monitoring, drug delivery systems, and electronic prosthetics.

Flexible circuit technology is also finding applications in emerging fields such as flexible displays and flexible solar panels. These technologies leverage the unique characteristics of flexible circuits to create lightweight, durable, and energy-efficient devices.

In conclusion, flexible circuit technology offers several advantages, including flexibility, size and weight reduction, enhanced reliability, and improved electrical performance. Its applications span across various industries, including consumer electronics, automotive, aerospace and defense, medical, and emerging fields. As technology continues to advance, the demand for flexible circuitry is expected to grow, leading to further innovations in design, materials, and manufacturing processes.