Exploring the Versatility of flexible circuits in Modern Electronics

Flexible circuits, also known as flex circuits or flexible printed circuit boards (PCBs), have revolutionized the world of modern electronics. With their unique properties and design flexibility, flexible circuits have become an essential component in various industries, including aerospace, automotive, medical, and consumer electronics. In this article, we will explore the versatility of flexible circuits and their applications in different electronic devices.

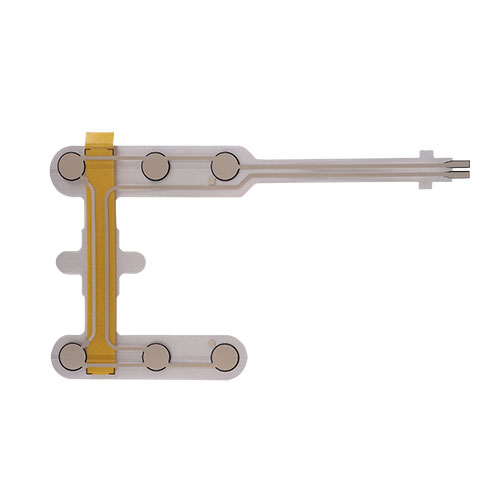

Flex circuits are made from thin, flexible materials, such as polyimide or polyester, that can be easily bent, twisted, and folded. Unlike rigid PCBs, which are made from rigid materials like FR4 or ceramic, flexible circuits offer unmatched design possibilities due to their ability to conform to curved or irregular surfaces. This flexibility allows designers to create highly compact and lightweight electronic devices, making them ideal for applications where space and weight are critical, such as in aerospace and wearable technology.

One of the main advantages of flexible circuits is their ability to reduce the number of interconnects or solder joints compared to traditional rigid PCBs. In flex circuits, the conductive traces are directly printed or etched onto the flexible substrate, eliminating the need for bulky cables or connectors. This simplifies the assembly process, reduces the overall size of the device, and enhances its reliability by minimizing the risk of loose connections or failures.

Flexible circuits also offer excellent resistance to vibration, shock, and thermal cycling, making them ideal for use in rugged environments. They can withstand extreme temperatures and are highly resistant to moisture and chemicals, ensuring their reliability and longevity even in harsh conditions. These properties make flex circuits suitable for automotive applications, where they can be used in engine control units, dashboards, and lighting systems, among others.

Furthermore, flexible circuits can be easily integrated into three-dimensional structures, enabling complex designs that were previously impossible. This property is especially valuable in the medical industry, where flexible circuits are used in devices like pacemakers, hearing aids, and medical implants. Their ability to conform to the body's contours allows for comfortable and discreet designs, while their durability ensures their continuous functionality over time.

Another application of flexible circuits is in consumer electronics, where they are used in smartphones, tablets, and wearable devices. The flexibility of the circuits enables manufacturers to create sleek, slim devices with innovative form factors. Flexible displays, for example, have gained popularity in recent years due to their ability to bend and curve. These displays are made possible by integrating flex circuits with flexible OLED panels, resulting in stunning and immersive visual experiences.

In conclusion, flexible circuits have revolutionized the world of electronics through their unique properties and design flexibility. Their ability to conform to curved surfaces, reduce interconnects, withstand harsh environments, and integrate into three-dimensional structures has opened up new possibilities for designers in various industries. Whether in aerospace, automotive, medical, or consumer electronics, flexible circuits have become an essential component, enabling the creation of smaller, lighter, and more versatile electronic devices.