Vincentzeng

Leave a messageMaterial:PET/PC/PP

Thickness:0.05mm-2.0 mm Structure

Overlay with printing+Rear Adhesive

Description:

Touch Flat Overlay

Keys embossed Overlay

Application:

Remote controller,Fridge,Washing machine,Medical instrument

Overlay is a popular and essential component in various industries, such as automotive, electronics, aerospace, and construction. It is a thin layer that is applied on top of a base material to enhance its functionality, durability, or appearance. Overlay manufacturers play a crucial role in meeting the diverse needs of different industries by producing high-quality Overlays.

The process of overlay manufacturing involves several stages, starting with the selection of materials. Depending on the desired properties of the overlay, manufacturers choose suitable materials such as metals, polymers, ceramics, or composites. These materials are then processed to create a thin sheet or film. The next step involves coating or laminating the base material with the overlay using adhesives, heat, pressure, or a combination of these methods.

Overlay manufacturers use advanced technologies and techniques to ensure the quality and performance of their products. They invest in research and development to develop new materials and processes that meet the evolving demands of industries. For instance, they may develop overlays with high heat resistance, chemical resistance, or electrical conductivity to meet specific requirements in the automotive or electronics industry.

One of the key considerations in overlay manufacturing is the adhesion between the overlay and the base material. Manufacturers use various methods to ensure a strong bond, such as surface preparation, chemical treatments, or plasma treatments. They also conduct rigorous testing to verify the adhesion strength, durability, and other performance characteristics of their overlays.

In addition to performance, overlay manufacturers also focus on the aesthetic aspects of their products. They offer a wide range of colors, finishes, textures, and patterns to meet the design requirements of different industries. For example, automotive overlays may have a metallic finish, while electronic overlays may have a matte or glossy appearance.

Overlay manufacturers serve a diverse customer base, including original equipment manufacturers (OEMs), distributors, and end-users. They work closely with their customers to understand their specific needs and requirements. This collaboration allows manufacturers to customize overlays according to the desired dimensions, thickness, and properties. They also provide technical support and guidance to help customers select the most appropriate overlays for their applications.

Quality control is a critical aspect of overlay manufacturing. Manufacturers implement stringent quality control measures throughout the production process to ensure that their overlays meet the highest standards. This includes regular inspection of raw materials, in-process monitoring, and final product testing. By adhering to strict quality control protocols, overlay manufacturers can ensure that their products consistently meet or exceed customer expectations.

Overlay manufacturers also prioritize sustainability and environmental responsibility. They strive to minimize waste generation, reduce energy consumption, and use eco-friendly materials and processes whenever possible. This commitment to sustainability helps them meet the increasing demand for environmentally friendly products and aligns with global efforts to minimize the environmental impact of industrial production.

In conclusion, overlay manufacturers play a vital role in providing high-quality overlays for various industries. Through their expertise, advanced technologies, and commitment to quality, they meet the diverse needs of customers and contribute to the development of innovative and sustainable solutions. As industries continue to evolve, overlay manufacturers will continue to adapt and innovate to meet the changing demands of the market.

13+ years experience work for membrane switch, overlay and nameplate products for our team.

One-stop process for membrane switch&product identification

Fully technology support from design to Mass Production.

Keep Improving by Quality First &Best Service to exceed customer’s expectations

Rapid Prototype Membrane Switches and Overlays by Fully automatic digital printing equipment + Automatic digital cutting prototype machine

5-7 days from design for approval.

Fully automatic digital printed graphics

Fully automatic digital die cut size

Automatic Screen printed graphics

Automatic Rotary printed graphics

Transparent tinted window options

Additional components such as rubber keypad assemblies

Backlighting options such as Light Guide Plate (LGP),Light Emitting Diodes (LED)

The company integrates design, research and development,manufacture and sales as one of the comprehensive enterprise.

Kunshan Begao Electronic Technology Co., Ltd. specializes in the design and production of membrane switch, overlay, flexible switch, label&Nameplate and capacitive touch circuit products. We Have a 100,000-level standard dust-free workshop, imported professional production equipment and a technical team with an experience of more than 10 years in the industry.

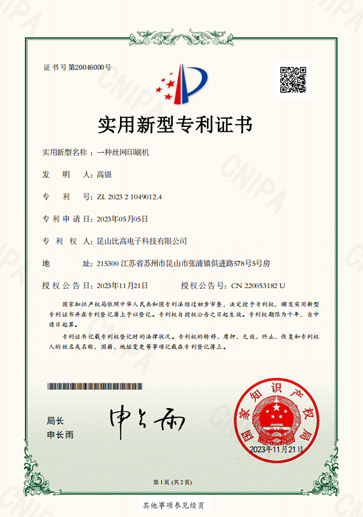

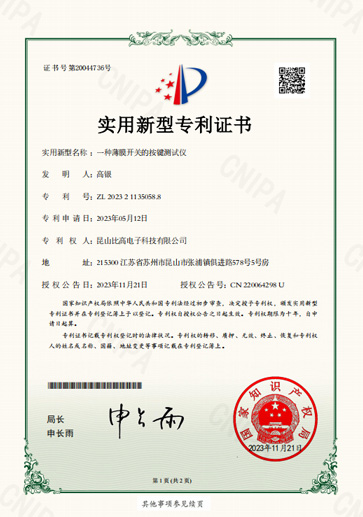

And we have acquired ISO9001:2008 international quality system and more than 18 professional technology patents and all the materials used meet the RoHS test standards.

Establish a stable and cooperative relationship with well-known domestic and foreign electronics enterprises such as: Sensata, Flextronics, Joyoung,Leadman, Zola, Zoomlion

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED