Vincentzeng

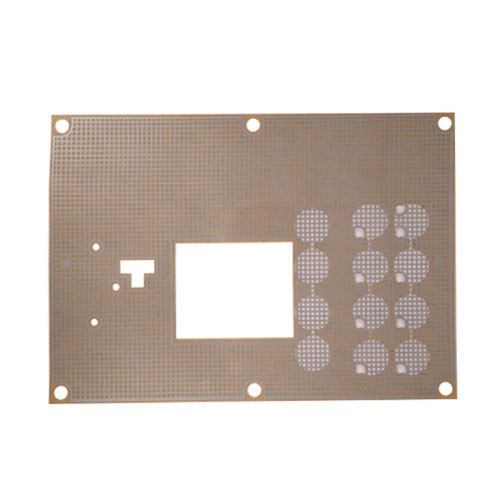

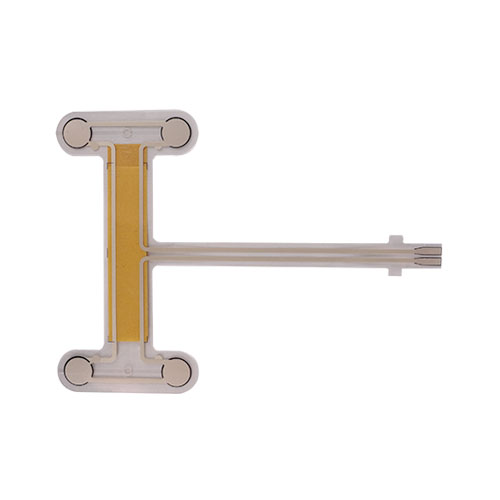

Leave a messageMaterial:PET/Black PET

Thickness:0.125 mm--0.188mm

Structure :

Upper switch+spacer+Lower switch+Rear adhesive

Description:

Touch flat flexible switch

Flexible switch with keys embossed

Flexible switch with metal domes

Capacitive touch flexible switch

flexible circuits, also known as flex circuits or flexible printed circuit boards (PCBs), are a type of electronic assembly comprising conductive strips laid on a flexible substrate material. These circuits provide a high degree of flexibility, allowing them to be bent, twisted, and folded to accommodate various form factors. In this text, we will delve deeper into the topic of flexible circuits, exploring their advantages, applications, and manufacturing processes.

One of the key advantages of flexible circuits is their ability to save space. Unlike traditional rigid PCBs, flex circuits can be designed to fit into tight spaces, enabling electronic devices like smartphones and wearables to become smaller and more lightweight. Their flexibility also allows for three-dimensional configurations, making them the ideal choice for curved displays and other curved surfaces.

Furthermore, flexible circuits offer a high level of reliability. With fewer interconnections and soldered joints, there are fewer points of failure. This reduces the risk of electrical shorts or open circuits, improving the overall durability and lifespan of the device.

Flex circuits are commonly used in a wide range of applications. In the aerospace industry, for example, they are utilized in avionics systems, where their lightweight and compact nature are highly advantageous. They can also be found in automotive electronics, medical devices, consumer electronics, and many other industries. Their ability to withstand extreme temperatures and vibrations, as well as their resistance to moisture and chemicals, make them suitable for these demanding environments.

The manufacturing process of flexible circuits involves several steps. It typically begins with the creation of a flexible substrate, such as polyimide or polyester film. The conductive traces are then screen-printed or etched onto the substrate, using methods similar to those used in traditional PCB manufacturing. Any necessary vias or through-hole connections are created, and components may be mounted using surface mount technology (SMT) or other methods. Finally, the flexible circuit is coated with a protective layer to safeguard the circuitry from external elements.

There are two main types of flexible circuits: single-sided and multi-layered. Single-sided flex circuits consist of a single layer of conductive traces, while multi-layered flex circuits have multiple interconnected layers. Multi-layered flex circuits offer higher circuit density and enhanced functionality, but they are more complex to manufacture.

In recent years, there have been advancements in flexible circuit technology, such as the development of stretchable circuits. These circuits can stretch and conform to irregular shapes, opening up new possibilities in wearable electronics and medical devices.

In conclusion, flexible circuits provide numerous advantages in terms of space-saving, reliability, and versatility. Their ability to conform to various form factors makes them an invaluable component in modern electronic devices. From smartphones to medical implants, flexible circuits continue to revolutionize the electronics industry, enabling the creation of smaller, lighter, and more innovative products.

13+ years experience work for membrane switch, overlay and nameplate products for our team.

One-stop process for membrane switch&product identification

Fully technology support from design to Mass Production.

Keep Improving by Quality First &Best Service to exceed customer’s expectations

Rapid Prototype Membrane Switches and Overlays by Fully automatic digital printing equipment + Automatic digital cutting prototype machine

5-7 days from design for approval.

Fully automatic digital printed graphics

Fully automatic digital die cut size

Automatic Screen printed graphics

Automatic Rotary printed graphics

Transparent tinted window options

Additional components such as rubber keypad assemblies

Backlighting options such as Light Guide Plate (LGP),Light Emitting Diodes (LED)

The company integrates design, research and development,manufacture and sales as one of the comprehensive enterprise.

Kunshan Begao Electronic Technology Co., Ltd. specializes in the design and production of membrane switch, overlay, flexible switch, label&Nameplate and capacitive touch circuit products. We Have a 100,000-level standard dust-free workshop, imported professional production equipment and a technical team with an experience of more than 10 years in the industry.

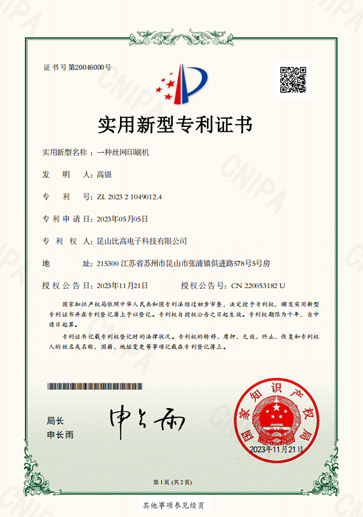

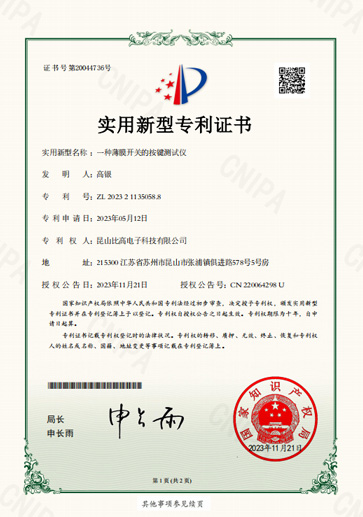

And we have acquired ISO9001:2008 international quality system and more than 18 professional technology patents and all the materials used meet the RoHS test standards.

Establish a stable and cooperative relationship with well-known domestic and foreign electronics enterprises such as: Sensata, Flextronics, Joyoung,Leadman, Zola, Zoomlion

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED