Vincentzeng

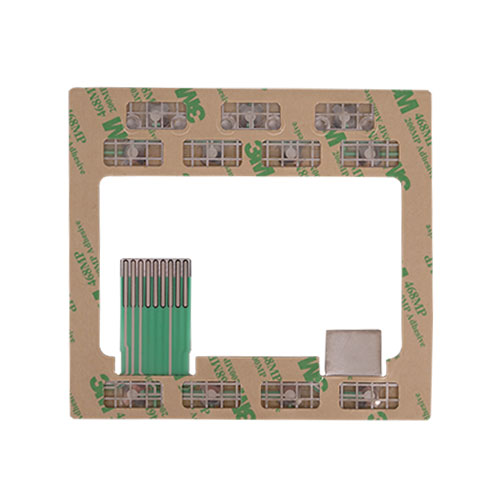

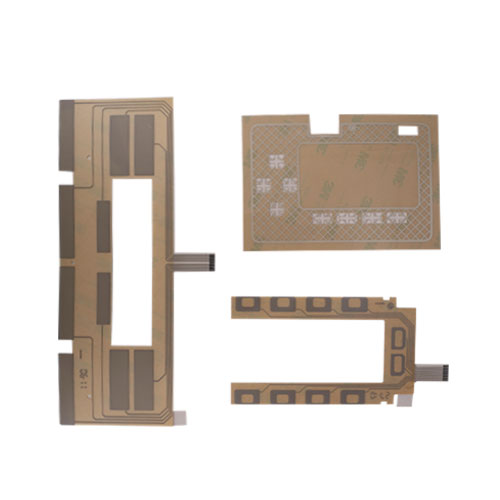

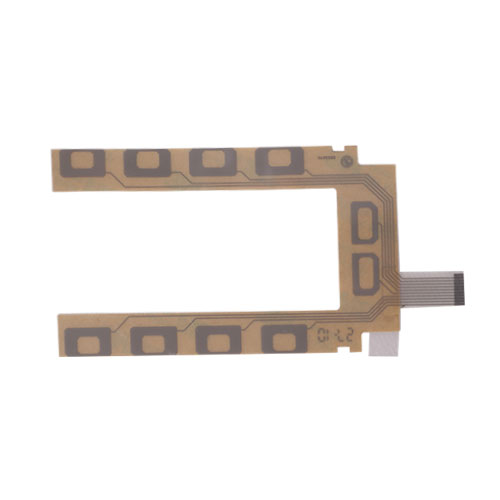

Leave a messageMaterial:PET/Black PET

Thickness:0.125 mm--0.188mm

Structure :

Upper switch+spacer+Lower switch+Rear adhesive

Description:

Touch flat flexible switch

Flexible switch with keys embossed

Flexible switch with metal domes

Capacitive touch flexible switch

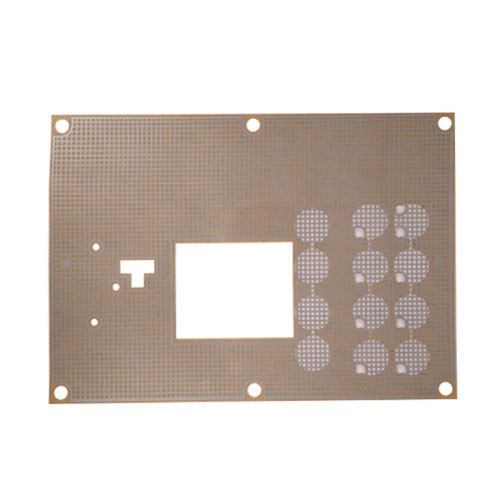

flexible circuit fabrication, also known as flexible printed circuit board (PCB) fabrication, is the process of creating electronic circuits that are designed to be flexible, bendable, and lightweight. This type of circuit fabrication allows for greater design flexibility and versatility compared to traditional rigid PCBs.

There are several methods used in Flexible circuit fabrication, each with its own advantages and limitations. The most common method is the additive process, which involves depositing conductive material onto a flexible substrate using various techniques such as screen printing, inkjet printing, or electroplating. This method allows for precise placement of the conductive traces and can create complex circuit patterns.

Another method used in flexible circuit fabrication is the subtractive process, where a conductive material is deposited onto a flexible substrate and then unwanted material is removed through etching or laser ablation. This method allows for high precision and can create fine line widths and spacings.

A third method used in flexible circuit fabrication is the hybrid process, which combines elements of the additive and subtractive processes. This method allows for greater flexibility in circuit design and can create more intricate and complex circuit patterns.

Flexible circuit fabrication can be done using a variety of materials, including flexible substrates such as polyimide, polyester, or PEN (polyethylene naphthalate), and conductive materials such as copper, silver, or carbon. The choice of materials depends on the specific requirements of the circuit, such as flexibility, temperature resistance, and chemical resistance.

The fabrication process begins with the design of the circuit using computer-aided design (CAD) software. The circuit design is then transferred onto the flexible substrate using a photoresist or photoetch process. The conductive material is then deposited onto the substrate using the chosen method, such as printing or electroplating. After the conductive traces are formed, a protective coating is applied to protect the circuit from environmental factors, such as moisture and heat.

Flexible circuit fabrication offers several advantages over rigid PCBs. Firstly, flexible circuits are lightweight and thin, making them suitable for applications where size and weight are critical factors, such as wearable devices and medical implants. Secondly, flexible circuits can be bent or twisted without losing functionality, allowing for greater design freedom and versatility. Additionally, flexible circuits are more resistant to vibration and shock compared to rigid PCBs, making them suitable for applications in harsh environments.

Flexible circuits are used in a wide range of applications, including consumer electronics, automotive electronics, medical devices, aerospace, and defense. They are commonly found in smartphones, tablets, laptops, fitness trackers, automotive dashboards, and medical implants. The flexibility and lightweight nature of flexible circuits make them particularly suitable for applications where space is limited or where the circuit needs to conform to a curved or irregular shape.

In conclusion, flexible circuit fabrication is the process of creating electronic circuits that are flexible, bendable, and lightweight. This fabrication method offers greater design flexibility and versatility compared to traditional rigid PCBs, and is used in a wide range of applications. The choice of materials and fabrication method depends on the specific requirements of the circuit, and the fabrication process involves designing the circuit, transferring the design onto the flexible substrate, depositing the conductive traces, and applying a protective coating. Flexible circuits are used in various industries and offer advantages such as lightweight, flexibility, and resistance to vibration and shock.

13+ years experience work for membrane switch, overlay and nameplate products for our team.

One-stop process for membrane switch&product identification

Fully technology support from design to Mass Production.

Keep Improving by Quality First &Best Service to exceed customer’s expectations

Rapid Prototype Membrane Switches and Overlays by Fully automatic digital printing equipment + Automatic digital cutting prototype machine

5-7 days from design for approval.

Fully automatic digital printed graphics

Fully automatic digital die cut size

Automatic Screen printed graphics

Automatic Rotary printed graphics

Transparent tinted window options

Additional components such as rubber keypad assemblies

Backlighting options such as Light Guide Plate (LGP),Light Emitting Diodes (LED)

The company integrates design, research and development,manufacture and sales as one of the comprehensive enterprise.

Kunshan Begao Electronic Technology Co., Ltd. specializes in the design and production of membrane switch, overlay, flexible switch, label&Nameplate and capacitive touch circuit products. We Have a 100,000-level standard dust-free workshop, imported professional production equipment and a technical team with an experience of more than 10 years in the industry.

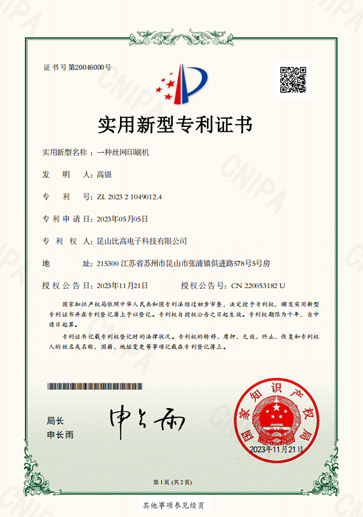

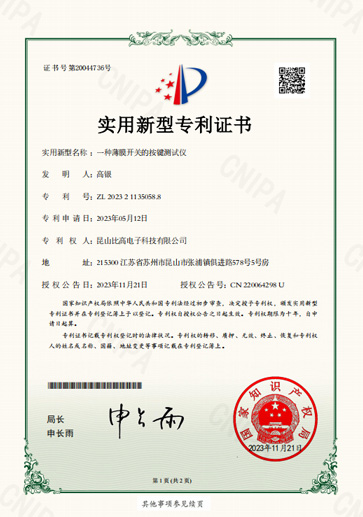

And we have acquired ISO9001:2008 international quality system and more than 18 professional technology patents and all the materials used meet the RoHS test standards.

Establish a stable and cooperative relationship with well-known domestic and foreign electronics enterprises such as: Sensata, Flextronics, Joyoung,Leadman, Zola, Zoomlion

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED