Vincentzeng

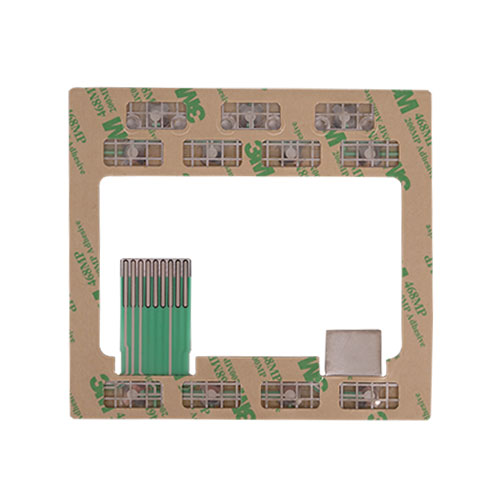

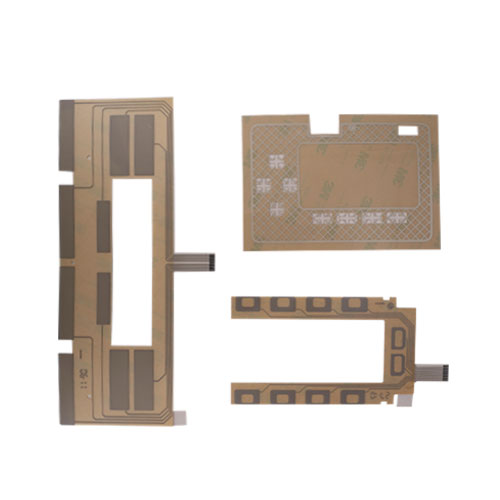

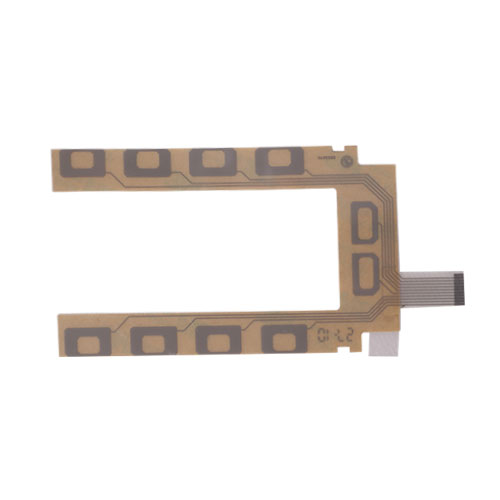

Leave a messageMaterial:PET/Black PET

Thickness:0.125 mm--0.188mm

Structure :

Upper switch+spacer+Lower switch+Rear adhesive

Description:

Touch flat flexible switch

Flexible switch with keys embossed

Flexible switch with metal domes

Capacitive touch flexible switch

flexible circuits, also known as flex circuits, refer to printed circuit boards (PCBs) that are constructed using flexible materials. These materials allow the circuit to be bent, twisted, and folded, making them ideal for applications where traditional rigid PCBs are not suitable.

The development of flexible circuits has revolutionized the electronics industry, as they offer numerous advantages over their rigid counterparts. Firstly, their flexibility enables them to be used in applications where space is limited or unconventional shapes are required. For example, they can be easily integrated into wearable devices, such as smartwatches and fitness trackers, allowing for comfortable and unobtrusive designs.

Flex circuits are also highly durable, as they are less prone to damage from vibrations, shocks, and bending. This makes them ideal for applications in industries that require rugged and reliable electronics, such as automotive and aerospace. Additionally, flexible circuits are lightweight and compact, saving space and reducing weight in various electronic devices.

Furthermore, flex circuits offer superior signal integrity and electrical performance compared to rigid PCBs. Their construction allows for shorter signal paths, reducing noise and impedance issues, resulting in better signal quality and faster transmission speeds. This makes them suitable for high-frequency applications, such as in telecommunications and data transmission.

The flexibility of these circuits also makes them easier to install and remove, reducing assembly time and cost. They can be bent and manipulated to fit into tight spaces or complex shapes, eliminating the need for connectors and adapters. This simplifies the assembly process and reduces the risk of connection failures.

Flexible circuits can be manufactured using various techniques, such as adding a flexible layer to traditional rigid PCBs or using roll-to-roll processes. The materials used for flex circuits include polyimide, polyester, and polyethylene terephthalate (PET). These materials offer excellent thermal stability, allowing the circuits to withstand high temperatures during manufacturing processes like soldering.

One common type of flexible circuit is the single-sided flexible circuit, which consists of a conductive layer laminated onto a flexible substrate. It is typically used in applications that require lightweight and compact designs, such as handheld devices and medical equipment.

Another type is the double-sided flexible circuit, which has conductive layers on both sides of the flexible substrate. This allows for more complex circuit designs and increased circuit density. Double-sided flex circuits are commonly used in more advanced electronic devices, such as smartphones and tablets.

Multilayer flexible circuits contain multiple layers of conductive material separated by dielectric layers. They offer even greater circuit density and can accommodate more complex circuit designs. This type of flex circuit is used in high-performance devices, such as aerospace and military electronics.

In conclusion, flexible circuits have revolutionized the electronics industry by offering numerous advantages over traditional rigid PCBs. Their flexibility, durability, lightweight, and compactness make them suitable for a wide range of applications, from wearable devices to automotive and aerospace electronics. Furthermore, their superior signal integrity and electrical performance make them ideal for high-frequency applications. With their various types and manufacturing techniques, flexible circuits continue to be at the forefront of electronic design and innovation.

13+ years experience work for membrane switch, overlay and nameplate products for our team.

One-stop process for membrane switch&product identification

Fully technology support from design to Mass Production.

Keep Improving by Quality First &Best Service to exceed customer’s expectations

Rapid Prototype Membrane Switches and Overlays by Fully automatic digital printing equipment + Automatic digital cutting prototype machine

5-7 days from design for approval.

Fully automatic digital printed graphics

Fully automatic digital die cut size

Automatic Screen printed graphics

Automatic Rotary printed graphics

Transparent tinted window options

Additional components such as rubber keypad assemblies

Backlighting options such as Light Guide Plate (LGP),Light Emitting Diodes (LED)

The company integrates design, research and development,manufacture and sales as one of the comprehensive enterprise.

Kunshan Begao Electronic Technology Co., Ltd. specializes in the design and production of membrane switch, overlay, flexible switch, label&Nameplate and capacitive touch circuit products. We Have a 100,000-level standard dust-free workshop, imported professional production equipment and a technical team with an experience of more than 10 years in the industry.

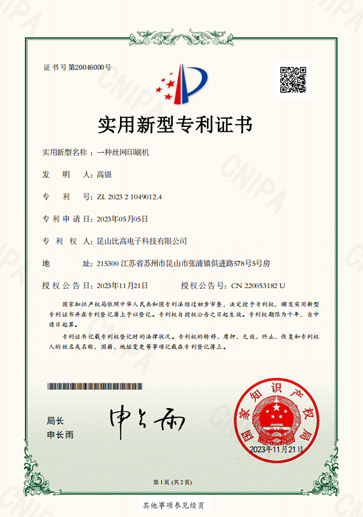

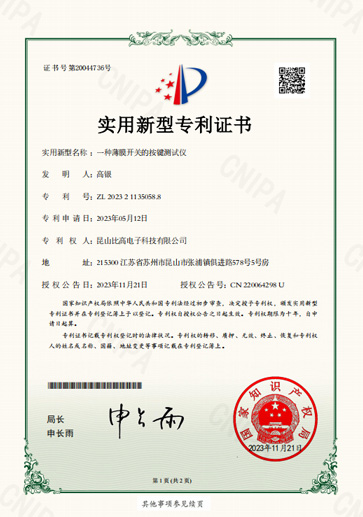

And we have acquired ISO9001:2008 international quality system and more than 18 professional technology patents and all the materials used meet the RoHS test standards.

Establish a stable and cooperative relationship with well-known domestic and foreign electronics enterprises such as: Sensata, Flextronics, Joyoung,Leadman, Zola, Zoomlion

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED