Vincentzeng

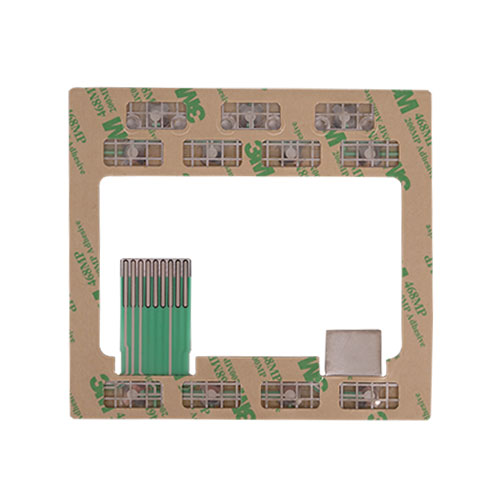

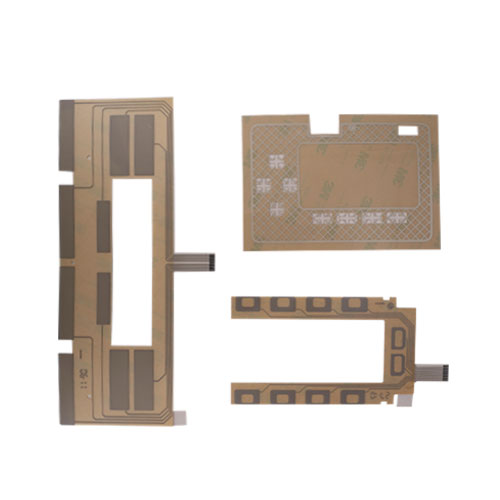

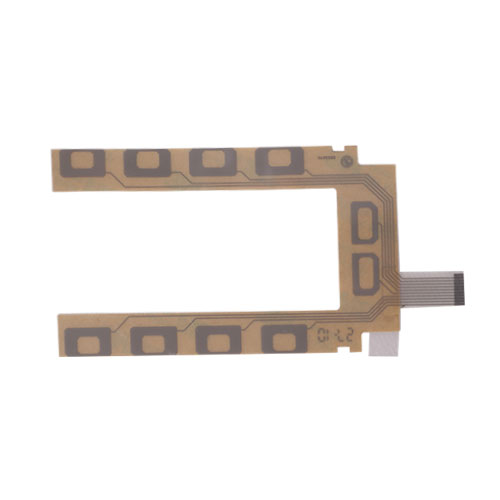

Leave a messageMaterial:PET/Black PET

Thickness:0.125 mm--0.188mm

Structure :

Upper switch+spacer+Lower switch+Rear adhesive

Description:

Touch flat flexible switch

Flexible switch with keys embossed

Flexible switch with metal domes

Capacitive touch flexible switch

flexible circuit boards, also known as flex circuits, are a type of printed circuit board (PCB) that can bend, twist, and fold without breaking. They are widely used in various electronic devices, such as smartphones, tablets, wearable devices, and medical equipment.

Flex circuits are composed of a thin, flexible substrate material, like polyimide or polyester, that is coated with a layer of conductive material, usually copper, on one or both sides. The conductive traces are etched onto the substrate using a photolithographic process, similar to the one used in traditional PCB manufacturing. These traces can carry electrical signals and power between different components and connectors on the circuit board.

One of the key advantages of flex circuits is their ability to bend and conform to different shapes and volumes. This allows for more compact and lightweight designs, as the circuit can be integrated into the device itself, rather than being housed in a separate rigid PCB. For example, in a smartphone, the flex circuit can be bent and folded to fit into the tight space behind the display, enabling the device to maintain a slim profile.

Flex circuits also offer excellent thermal and electrical properties. The thin substrate material has a low thermal resistance, allowing for efficient heat dissipation from the components. Additionally, the flexible nature of the circuit reduces the risk of solder joint fatigue, which can occur in traditional rigid PCBs due to constant mechanical stress. This makes flex circuits more reliable and durable, especially in applications that experience vibrations or frequent bending.

Another advantage of flex circuits is their ability to accommodate complex three-dimensional (3D) designs. By using a combination of bending, folding, and stacking, designers can create circuits that fit into unconventional shapes and spaces. This is particularly useful in miniaturized electronic devices, where every millimeter of space is crucial.

The manufacturing process of flex circuits is similar to that of rigid PCBs, but with some additional steps to ensure flexibility. The substrate material is usually coated with a layer of adhesive, which helps to bond the conductive material to the substrate and enhance its flexibility. The circuit is then assembled with components, connectors, and protective coatings, just like a traditional PCB.

Flex circuits have some limitations compared to rigid PCBs. They are generally more expensive to manufacture, due to the additional steps and materials involved. The flexibility of the circuit can also restrict the type and size of components that can be used, as some components may not be able to withstand the mechanical stress of bending or folding.

Despite these limitations, flex circuits have become increasingly popular in many industries due to their unique advantages. They have revolutionized the design of various electronic devices, enabling more compact, lightweight, and innovative products. The demand for flex circuits is expected to grow in the coming years, as the need for flexible and wearable electronics continues to rise.

In conclusion, Flexible circuit boards, or flex circuits, are a type of PCB that can bend, twist, and fold without breaking. They offer advantages such as compact design, excellent thermal and electrical properties, and the ability to accommodate complex 3D designs. Although they have some limitations, flex circuits have revolutionized electronic device design and are expected to continue playing a crucial role in the future of technology.

13+ years experience work for membrane switch, overlay and nameplate products for our team.

One-stop process for membrane switch&product identification

Fully technology support from design to Mass Production.

Keep Improving by Quality First &Best Service to exceed customer’s expectations

Rapid Prototype Membrane Switches and Overlays by Fully automatic digital printing equipment + Automatic digital cutting prototype machine

5-7 days from design for approval.

Fully automatic digital printed graphics

Fully automatic digital die cut size

Automatic Screen printed graphics

Automatic Rotary printed graphics

Transparent tinted window options

Additional components such as rubber keypad assemblies

Backlighting options such as Light Guide Plate (LGP),Light Emitting Diodes (LED)

The company integrates design, research and development,manufacture and sales as one of the comprehensive enterprise.

Kunshan Begao Electronic Technology Co., Ltd. specializes in the design and production of membrane switch, overlay, flexible switch, label&Nameplate and capacitive touch circuit products. We Have a 100,000-level standard dust-free workshop, imported professional production equipment and a technical team with an experience of more than 10 years in the industry.

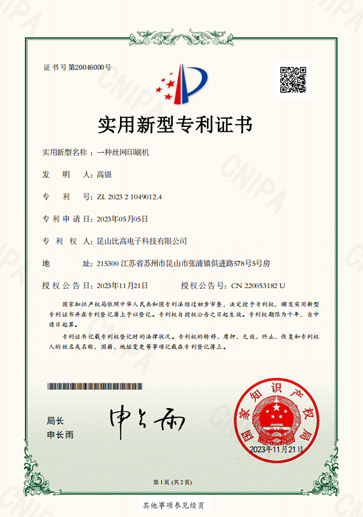

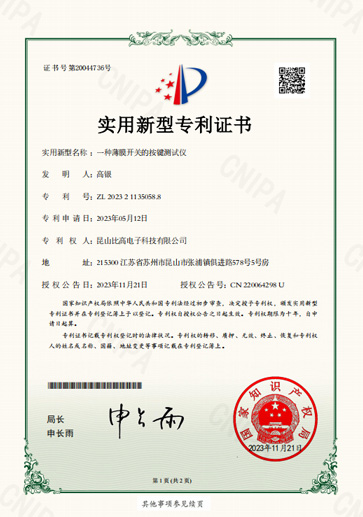

And we have acquired ISO9001:2008 international quality system and more than 18 professional technology patents and all the materials used meet the RoHS test standards.

Establish a stable and cooperative relationship with well-known domestic and foreign electronics enterprises such as: Sensata, Flextronics, Joyoung,Leadman, Zola, Zoomlion

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED