Vincentzeng

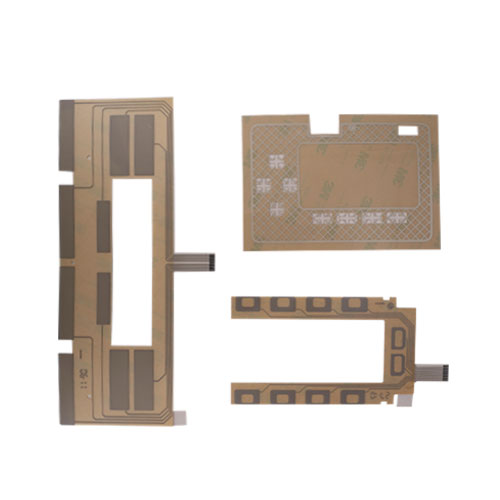

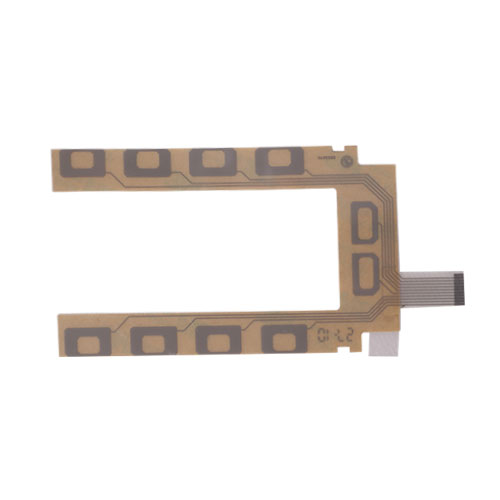

Leave a messageMaterial:PET/Black PET

Thickness:0.125 mm--0.188mm

Structure :

Upper switch+spacer+Lower switch+Rear adhesive

Description:

Touch flat flexible switch

Flexible switch with keys embossed

Flexible switch with metal domes

Capacitive touch flexible switch

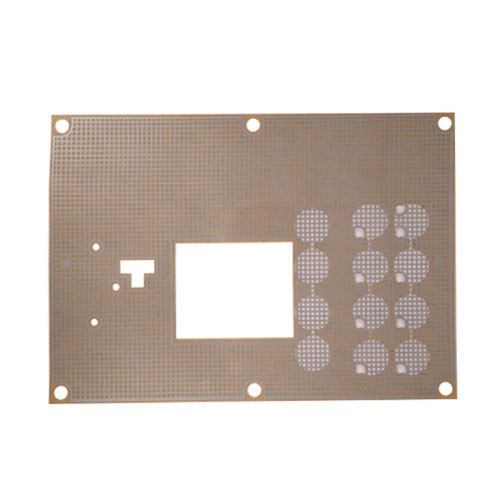

flexible circuit design, also known as flex circuit design or flex PCB design, refers to the process of designing and creating printed circuit boards (PCBs) that are flexible and can bend or twist. This design technique offers numerous advantages over traditional rigid PCBs, including space savings, improved reliability, and enhanced freedom in product design.

One of the key benefits of Flexible circuit design is its ability to save space. By allowing the circuit board to bend or flex, it can be easily integrated into tight or irregularly shaped spaces that would otherwise be inaccessible. This is especially beneficial in small electronic devices, such as smartphones, tablets, and wearable technology, where space is limited. Flexible circuits also allow for three-dimensional interconnection, which further maximizes space efficiency.

Another advantage of flexible circuit design is improved reliability. Unlike rigid PCBs, which are susceptible to cracking or breaking under stress or vibration, flexible circuits are highly resistant to mechanical stress and can withstand repeated bending, twisting, and flexing. This makes them ideal for applications that require frequent movement or are subjected to harsh environments. Additionally, the decreased number of interconnections in flexible circuits reduces the risk of contact failure and increases the overall reliability of the circuit board.

Flex PCB design also offers enhanced freedom in product design. The flexibility of the circuit board allows designers to create innovative and unique form factors, such as curved or even wearable electronics. This opens up new possibilities for product differentiation and can lead to more aesthetically pleasing and ergonomic designs. Furthermore, the ability to integrate multiple functions into a single Flexible circuit board simplifies assembly and reduces overall manufacturing costs.

When designing flexible circuits, several factors need to be considered. First, the mechanical requirements of the application should be carefully analyzed to determine the type and thickness of the flexible substrate material that will be used. Common materials include polyimide and polyester films, which offer excellent flexibility and electrical insulation properties. The choice of adhesive and protective coating materials is also critical to ensure mechanical and chemical stability.

The electrical requirements of the circuit should also be taken into account during the design phase. The layout of the circuit traces and components should be optimized to minimize signal loss, crosstalk, and electromagnetic interference. Proper grounding techniques and noise reduction measures should be implemented to maintain signal integrity. Additionally, the flexibility of the circuit should not negatively impact the electrical performance, and design guidelines for flexible circuits should be followed to ensure proper impedance control and manufacturability.

Prototyping and testing are crucial steps in flexible circuit design to verify the functionality and reliability of the design. Various testing methods, such as mechanical bending tests, thermal cycling, and electrical performance measurements, should be conducted to ensure that the flexible circuit meets the required specifications and standards.

In conclusion, flexible circuit design offers numerous advantages over traditional rigid PCBs, including space savings, improved reliability, and enhanced freedom in product design. However, careful consideration of mechanical and electrical requirements, as well as proper prototyping and testing, is crucial to ensure a successful flexible circuit design. With the increasing demand for smaller and more innovative electronic devices, flexible circuit design is becoming increasingly important in the field of electronics.

13+ years experience work for membrane switch, overlay and nameplate products for our team.

One-stop process for membrane switch&product identification

Fully technology support from design to Mass Production.

Keep Improving by Quality First &Best Service to exceed customer’s expectations

Rapid Prototype Membrane Switches and Overlays by Fully automatic digital printing equipment + Automatic digital cutting prototype machine

5-7 days from design for approval.

Fully automatic digital printed graphics

Fully automatic digital die cut size

Automatic Screen printed graphics

Automatic Rotary printed graphics

Transparent tinted window options

Additional components such as rubber keypad assemblies

Backlighting options such as Light Guide Plate (LGP),Light Emitting Diodes (LED)

The company integrates design, research and development,manufacture and sales as one of the comprehensive enterprise.

Kunshan Begao Electronic Technology Co., Ltd. specializes in the design and production of membrane switch, overlay, flexible switch, label&Nameplate and capacitive touch circuit products. We Have a 100,000-level standard dust-free workshop, imported professional production equipment and a technical team with an experience of more than 10 years in the industry.

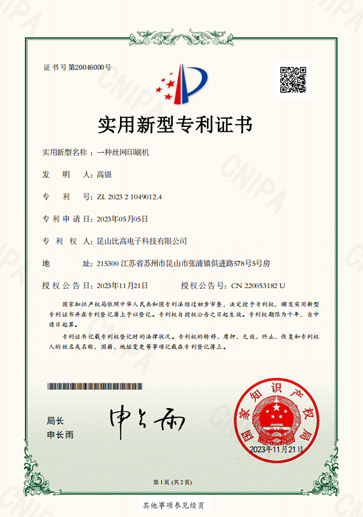

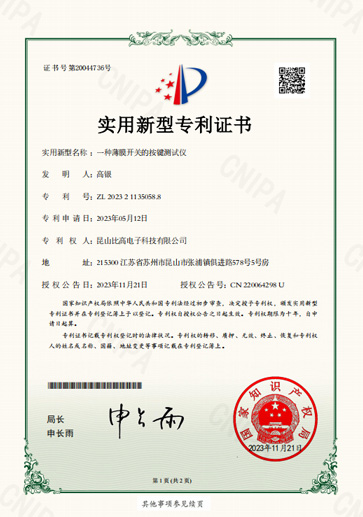

And we have acquired ISO9001:2008 international quality system and more than 18 professional technology patents and all the materials used meet the RoHS test standards.

Establish a stable and cooperative relationship with well-known domestic and foreign electronics enterprises such as: Sensata, Flextronics, Joyoung,Leadman, Zola, Zoomlion

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED