Vincentzeng

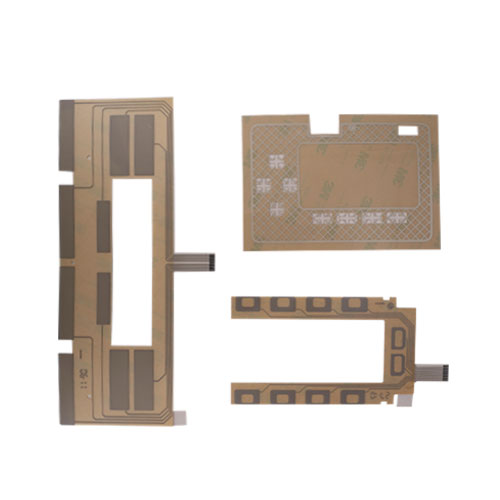

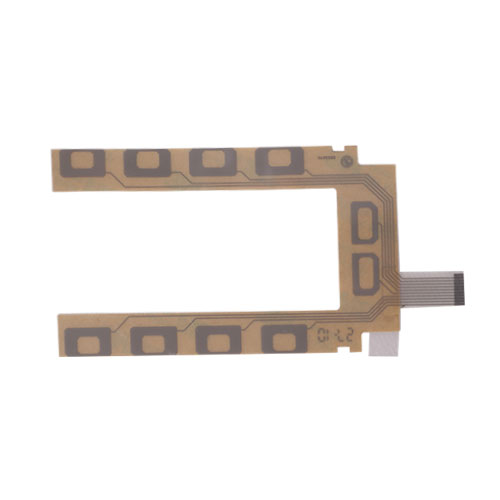

Leave a messageMaterial:PET/Black PET

Thickness:0.125 mm--0.188mm

Structure :

Upper switch+spacer+Lower switch+Rear adhesive

Description:

Touch flat flexible switch

Flexible switch with keys embossed

Flexible switch with metal domes

Capacitive touch flexible switch

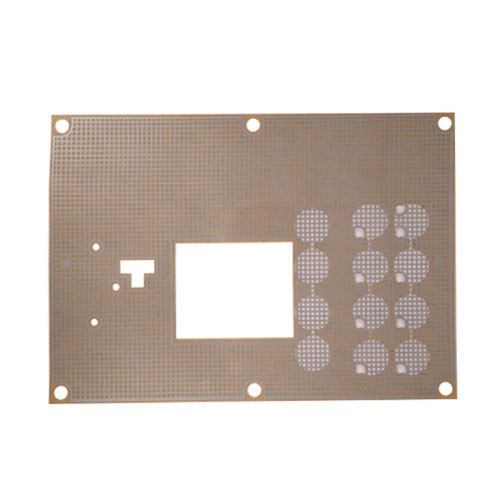

flexible circuit materials are essential components in various electronic devices. They enable the connection of electronic components and circuits with the ability to bend and flex without disrupting functionality. These materials consist of highly flexible substrates and conductive materials that allow for sturdy connections.

There are several types of Flexible circuit materials available in the market, each with its own unique properties and applications. The choice of material depends on factors such as cost, performance requirements, durability, and flexibility.

One common type of flexible circuit material is polyimide. Polyimide offers excellent thermal stability, high mechanical strength, and exceptional chemical resistance. It can handle high temperatures, making it suitable for applications that require exposure to extreme heat. Polyimide materials are commonly used in aerospace, automotive, and medical industries.

Another popular flexible circuit material is polyester. Polyester is known for its excellent dimensional stability and electrical insulation properties. It is often used in consumer electronics, such as smartphones and tablets, due to its cost-effectiveness and ability to withstand repetitive bending and flexing.

A newer entrant in the flexible circuit material market is liquid crystal polymer (LCP). LCP materials offer a unique combination of high-temperature resistance, low moisture absorption, and excellent electrical properties. They are primarily used in high-frequency applications, such as antennas and radar systems, where signal integrity is critical.

In addition to these individual materials, composite flexible circuit materials are also available. These materials combine multiple layers of different substrates, such as polyimide and polyester, to achieve specific performance requirements. For example, a composite material could feature a polyimide layer for thermal stability and a polyester layer for flexibility.

The choice of conductive material is also crucial in flexible circuit materials. Copper is the most commonly used conductive material due to its excellent conductivity and adhesion properties. However, silver and gold are sometimes used in applications that require higher conductivity or corrosion resistance.

To create flexible circuit materials, a combination of these substrates and conductive materials is typically laminated together using an adhesive. The flexible circuit material is then patterned using a combination of photolithography, etching, and printing techniques to create the desired circuitry and interconnection patterns.

In recent years, there have been advancements in flexible circuit materials to meet the ever-increasing demands of the electronics industry. For example, manufacturers have developed flexible circuit materials with reduced thickness and improved flexibility while maintaining their electrical and mechanical properties. These advancements have allowed for the integration of flexible circuits into smaller and more complex electronic devices.

In conclusion, flexible circuit materials are critical components in a wide range of electronic devices. The choice of material depends on factors such as performance requirements, durability, and flexibility. Polyimide, polyester, and liquid crystal polymer are some of the common materials used in flexible circuits. Copper is the most commonly used conductive material due to its excellent conductivity and adhesion properties. Advancements in flexible circuit materials have led to thinner and more flexible materials, enabling the integration of circuits into smaller and more complex devices.

13+ years experience work for membrane switch, overlay and nameplate products for our team.

One-stop process for membrane switch&product identification

Fully technology support from design to Mass Production.

Keep Improving by Quality First &Best Service to exceed customer’s expectations

Rapid Prototype Membrane Switches and Overlays by Fully automatic digital printing equipment + Automatic digital cutting prototype machine

5-7 days from design for approval.

Fully automatic digital printed graphics

Fully automatic digital die cut size

Automatic Screen printed graphics

Automatic Rotary printed graphics

Transparent tinted window options

Additional components such as rubber keypad assemblies

Backlighting options such as Light Guide Plate (LGP),Light Emitting Diodes (LED)

The company integrates design, research and development,manufacture and sales as one of the comprehensive enterprise.

Kunshan Begao Electronic Technology Co., Ltd. specializes in the design and production of membrane switch, overlay, flexible switch, label&Nameplate and capacitive touch circuit products. We Have a 100,000-level standard dust-free workshop, imported professional production equipment and a technical team with an experience of more than 10 years in the industry.

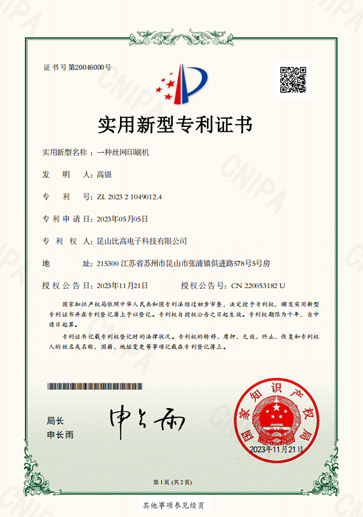

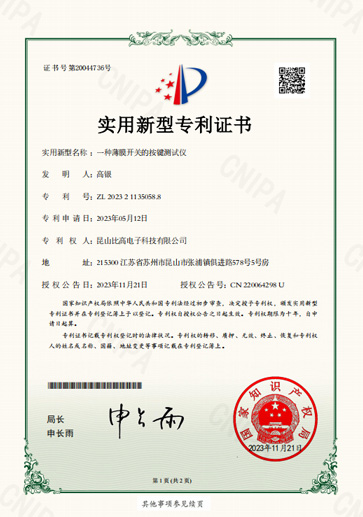

And we have acquired ISO9001:2008 international quality system and more than 18 professional technology patents and all the materials used meet the RoHS test standards.

Establish a stable and cooperative relationship with well-known domestic and foreign electronics enterprises such as: Sensata, Flextronics, Joyoung,Leadman, Zola, Zoomlion

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED